We Offer Innovating Solutions For Business Partners Troughout The World

Unique Solutions

Solutions For Everyone

Food

We are manufacturers of food handling equipment for companies within many different industries.

Non Food

Equipment that automates the process of handling materials during industrial activities, manufacturing, packaging, logistics.

Pharma

We have many years of experience making conveying systems for the transportation and handling of pharmaceutical products.

Food Handling Solutions

Nikodan is the right partner for companies in the food industry. We manufacture and deliver food handling systems, such as conveyor belts and other OEM solutions, which are important pieces to the production line. Whatever task you are facing, we are ready with an innovative solution.

Our know-how within the food industry is extensive. We are especially known for our high quality and great flexibility. As for documentation and delivery, it goes without saying that we take care of it. We move your product and make cleaning easier with our innovative, clean solutions. We look into the future and follow the current trends along with our customers.

Material Handling Solutions

We have many years of experience manufacturing material handling solutions, such as palletizers and pick-and-place robots, for the modern, industrial production. We manufacture solid systems for handling all things, like heavy bulk goods, fully operational, high-speed conveying systems for handling small materials, and units for gentle transportation of fragile products. Whatever the need, we design and manufacture lasting material handling solutions.

We design with the latest technologies within design- and management systems to reduce energy consumption, because we are aiming towards a brighter and greener future. Our systems are reliable and require minimal service and maintenance, which gives our customers a competitive advantage.

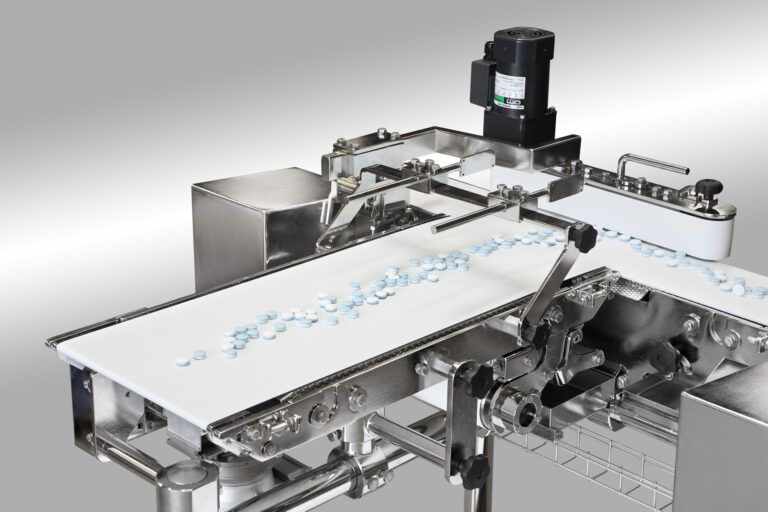

Pharmaceutical Equipment Solutions

At NIKODAN we are experts in making pharmaceutical equipment for solving complicated tasks in the medical industry. Manufacturing pharmaceutical equipment includes strict requirements regarding production safety, consistent quality, ongoing control, hygiene, and efficiency. These are just a some of the challenges we happily accept when working within the medical industry. We strive for greatness, and this is achieved by making well thought-out choices regarding material and components.

Innovation is the key to success. Our pharmaceutical equipment solutions are rarely the same, and therefore most projects need to be developed from scratch. This means that cooperation with the customer is essential to construct a good solution. Design and production are performed at our own facilities to ensure a short distance between our engineers and our clever hands in the production department. We are more than ready to make more solutions for the pharmaceutical industry.

OEM Solutions

Even though we have a vast expertise and experienced workers at NIKODAN, we acknowledge that cooperation with external partners can bring a lot of value to a production. We have a lot of business partners in relation to, for instance, automation and special machinery.

So if you manufacture special machines, ovens, machine plants, process plants, packing or palletizing machines etc., then contact us for future collaboration, to offer your customers a complete production solution. We have extensive experience in supplying customized standard conveyors and special machines, which are combined with other manufacturer’s products.