Unique Solutions

Inliner

Inliner

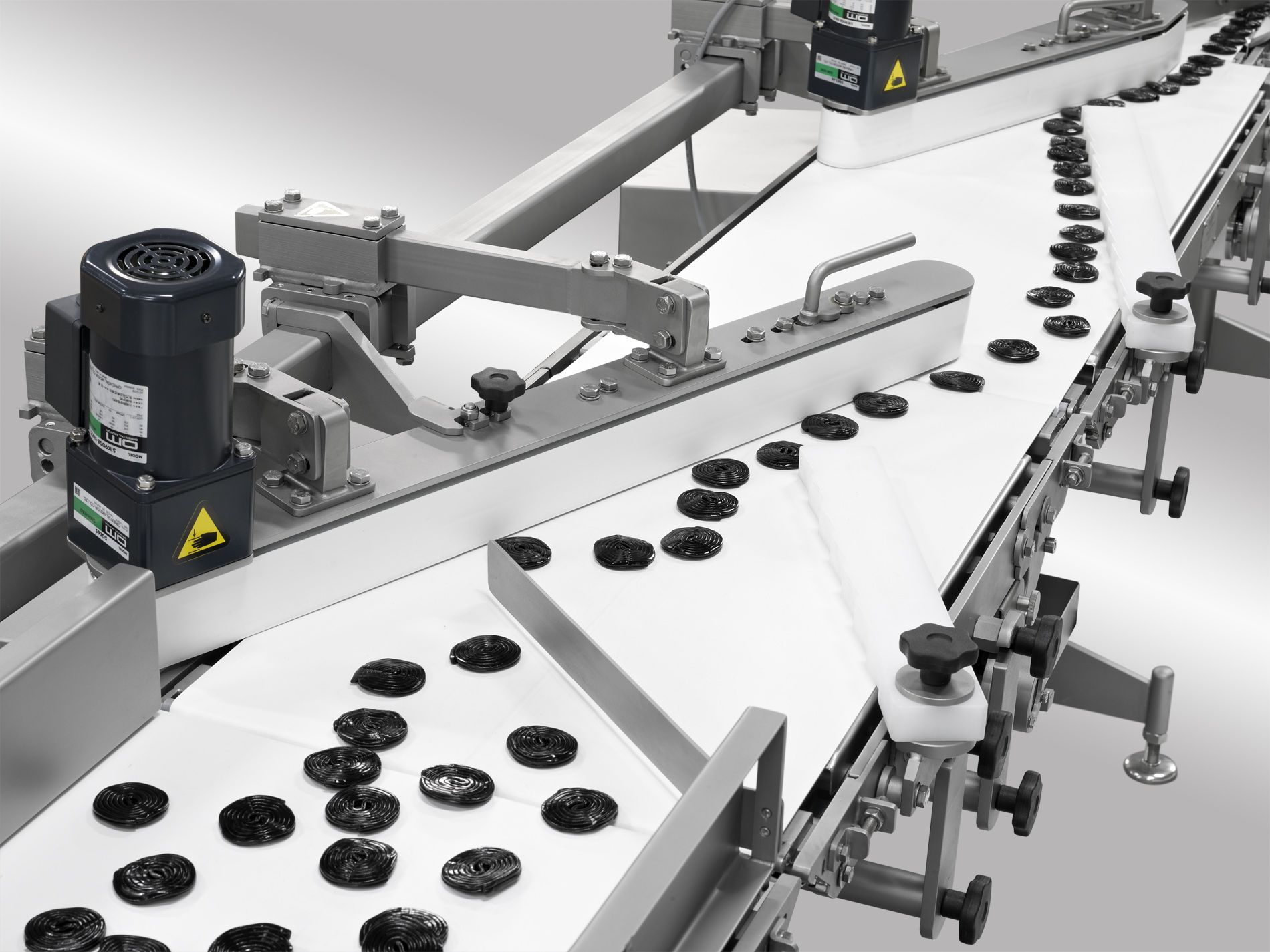

The inliner is a specific type of transporter in a conveyor system, that helps place products on the conveyor belt. This happens through side belts that line the products in a straight line as needed. After this, the products are arranged, ready for the next step in the production line, like an oven, a washer, further transportation or an infeed for packaging.

Size, speed and other specifications of the infeed conveyor system will be customized to any production's individual needs, to make sure that the unit is compatible with both the specific product and the packaging system. We make inliners for every type of product, from chewing gum, to cakes, to plastic trays. We've done them all! With an inliner unit as part of your production line, you are certain to get a consistent, automated delivery of products to the next step of your production line.

Possible customizations for the infeed can include general sizing, belt speed, material, motors, surface treatment, side belts, sensors, belt scrapers and cable trays. It's, for example, also possible to add lockable wheels to the inline, for a greater flexibility in removing the unit from the conveyor system, either for cleaning or for maintanence.

Advantages of the Inliner

- Lines up products as needed

- Sorts bulk products into straight lines

- Easy to disassemble for cleaning and maintenance

- Can be heavily customized to any production needs

- Hygienic design that meets all requirements and demands of the food industry

- Comes with full CE markings and documentation

If you're interested in more information on this conveyor solution and its options for customization or other NIKODAN conveyor solutions, contact us via our email or phone:

Product information:

Width: 150 - 250 - 350 mm

Height: 850 - 900 mm

Length: 1000 x 1000 - 1000 x 2000 mm

Speed: 5-50 m/min.

Belt type: Per agreement

Surface: Glassblown, grinded or polished

Cleaning: Belts can be taken off for easy cleaning or replacement

Protection class: IP65

Download brochuren

How to remove the belt from a NIKODAN conveyor:

lets stay in touch

contact us

+45 39 30 43 16

Fællesvej 9, DK-8766 Nr. Snede, Danmark

Nikodan@nikodan.dk