Innovating Nonfood Solutions For Business Partners Throughout The World

Unique Solutions

Material Handling Equipment

We make equipment that automates the process of handling materials during industrial activities, such as manufacturing, packaging, logistics etc. We have a wide operational range within the nonfood industry. We make automated material handling systems for e.g., transporting, dosing, sorting and packaging several different types of both food and nonfood items, as well as palletizers and pick and place robots for hoisting, stacking, and moving said items. On this page you will see some of our products that are not directly tied to the food or pharma industry, but we of course manufacture them to all industries, with the same high, hygienic quality. To learn more about our automated handling equipment and how it can help improve efficiency in your company, please contact us on salg@nikodan.dk or call us directly:

Our Nonfood Products

UVC Tunnel

The UVC Tunnel XP600 can be used to sterilize the surface of incoming objects, like boxes, cans, bagage and consumer goods. The UVC Tunnel can reduce up to 99% of all bacteria and virusses, depending on time and effect.

Dry Ice Dosage

Used for automatic dosing of dry ice and cryo pellets. The dosage amount is adjustable to your needs, and can dose up to 20 portions per minute.

Reject System

The Reject System helps sort through products on the conveyor, and pushes the rejected objects down a tract or a reject bin and out of the production line.

Attachless Infeeds

The attachless infeed is a unit that ensures correct delivery of the product(s) to the packing machine.

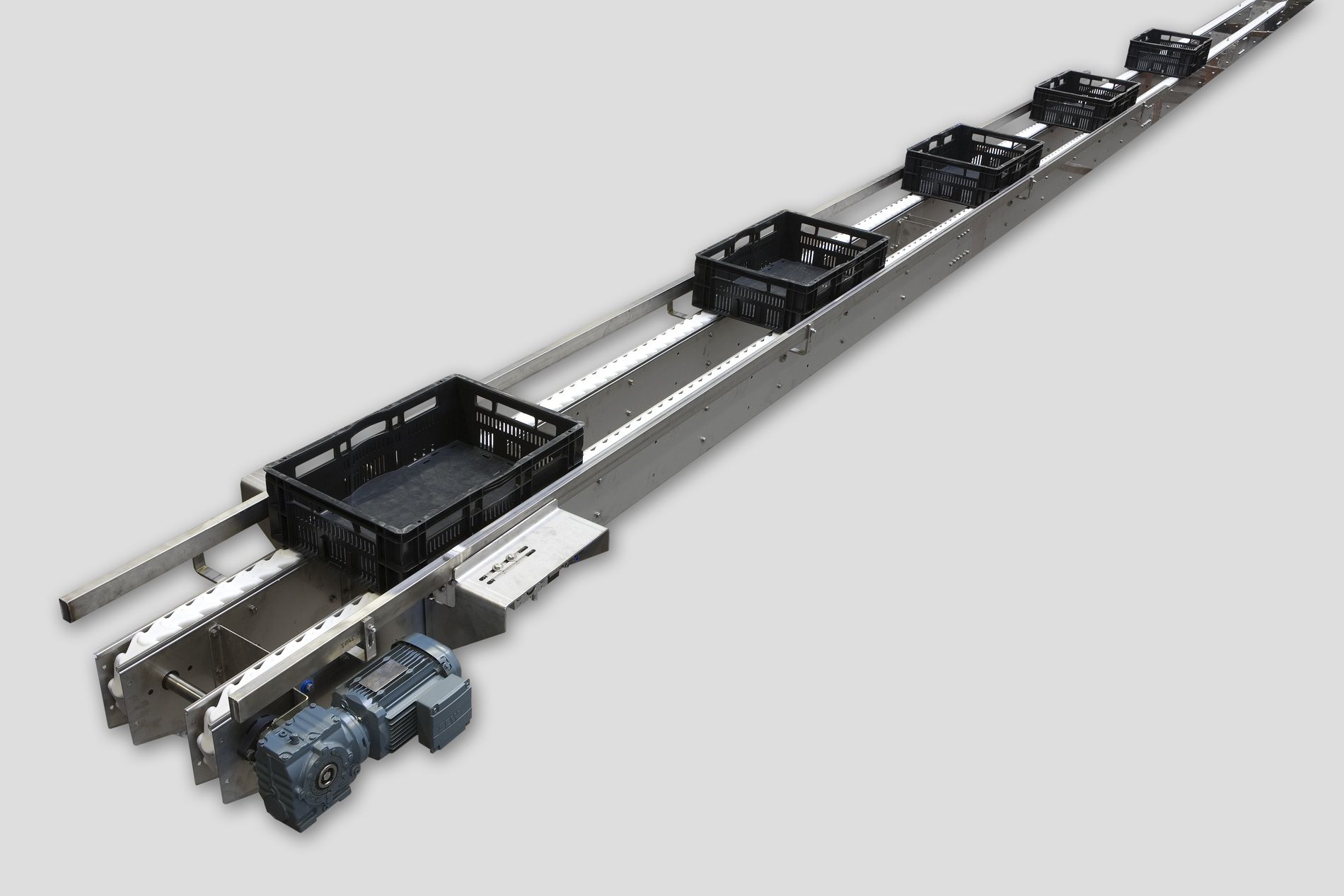

Conveyor System

NIKODAN offers multiple different, project customized, conveyor solutions to transport your products with ease from A to B.

Palletizing System

Different solutions for transporting and stacking pallets are available through our vast portefolio. Inform us of your palletizing need and we will engineer a solution.

Pick and Place robot

Pick and place automation speeds up the process of picking up parts or items and placing them in other locations.

Automating this process helps increase production rates. The robots handle repetitive tasks while freeing up human workers to focus on more complex work.

Lets stay in touch

Contact us

+45 39 304 316

Fællesvej 9, DK-8766 Nr. Snede, Danmark

Nikodan@nikodan.dk