Innovating Dairy Solutions For Business Partners Throughout The World

Unique Solutions

Dairy Manufacturing Equipment

We are manufacturers of dairy handling equipment within several industries, such as milk, butter, and cheese. We make conveyors and palletizing systems for the transportation, processing, and handling of cheese products, as well as crystallization belts for spray-drying milk products and stations for unpacking large amounts of butter for the baking industry. On this page you will find all these products, as well as others like washers, dryers, and turners that might be useful for your company. For more information and guidance about our products, contact us through the buttons below:

Our Dairy Products

Washer & Dryer

Cheeses are often washed before the final packaging. The cheeses are washed with brine before storage and thereby protected against unwanted bacterial growth. This conveyor system ensures that the washing and drying process is done correctly every time.

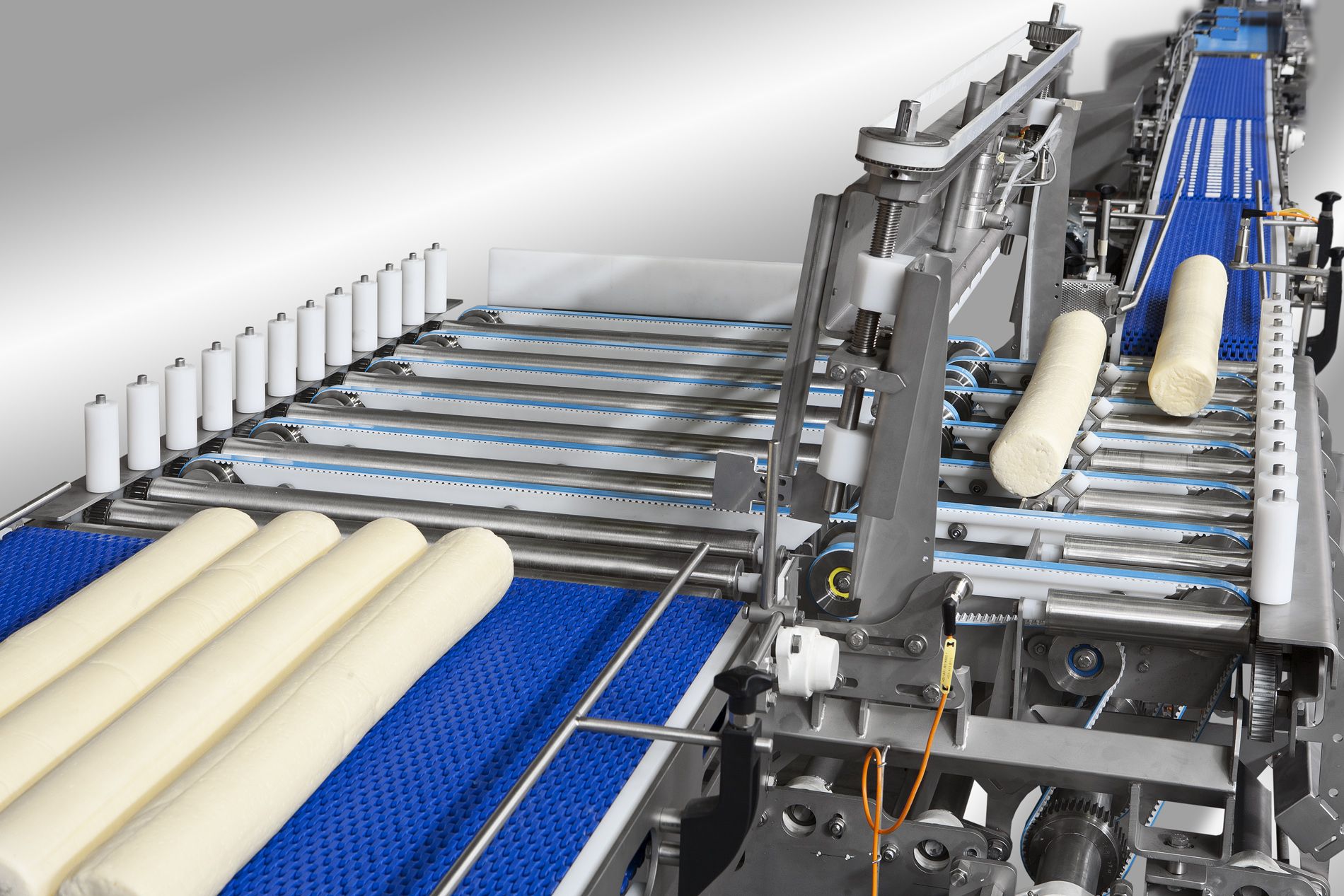

Inliners

The Inliner is a transporter with a hygenic design, optimized for the food industry, that can line products up symmetrically before being packed in a Flow wrapper.

Crystallization Belt

Fluidizing is widely used in the production of various powder products i.e milk powder and mashed potato. Warm air is distributed through a large number of small holes in the bottom plate in order to fluidize and crystalize, or dry up, the material.

Unpacking Station

The butter unpacking station is used for unwrapping heavy cartons (eg. butter cartons). Products delivered in boxes (often 25 kg) are handled in a more ergonomic correct position, as manual handling is minimized.

Rowfeeder

This transporter is used to move a row of products onto another conveyor, in a straight line.

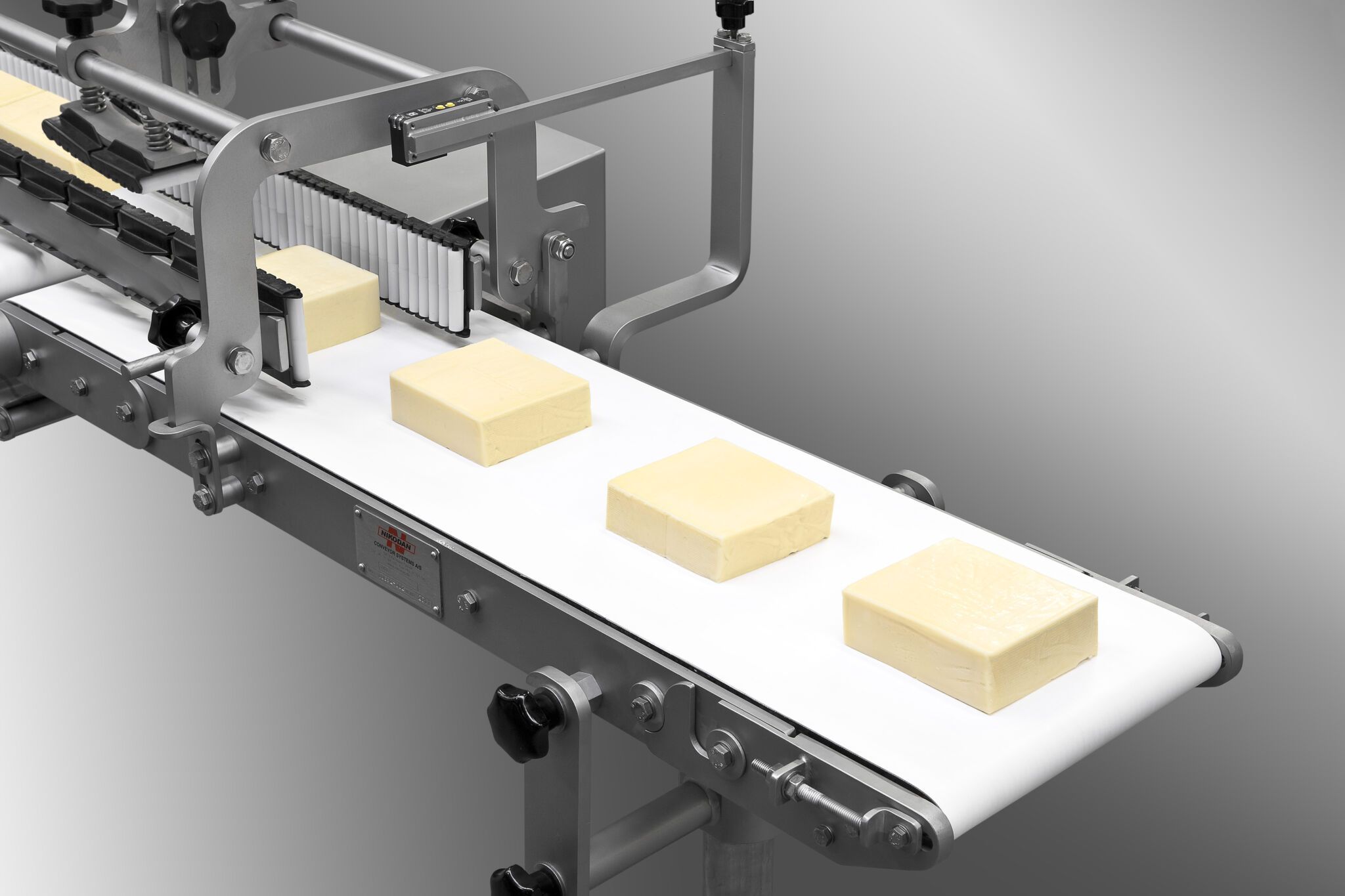

Attachless Infeeds

The attachless infeed is a unit that ensures correct delivery of the product(s) to the packing machine.

UVC Tunnel

The UVC Tunnel XP600 can be used to sterilize the surface of incoming dairy objects, cheese or butter. The UVC Tunnel can reduce up to 99% of all bacteria and virusses, depending on time and effect.

Pullnose

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Pick and Place robot

Pick and place automation speeds up the process of picking up parts or items and placing them in other locations.

Automating this process helps to increase production rates. Pick and place robots handle repetitive tasks while freeing up human workers to focus on more complex work.

As can be seen above, our process equipment for dairy includes dairy and cheese equipment e.g. for dairy material handling. Our range of dairy and cheese machinery also includes dairy spray dry equipment and after dairy products have been handled or transported on one of our machines, the products might be transferred to a machine for packing spray dried milk. For dairy conveying, we have conveyors for dairy foods that meet the strict hygiene requirements of the food industry and that can be manufactured according to your specifications.

Lets stay in touch

Contact us

+45 39 304 316

Fællesvej 9, DK-8766 Nr. Snede, Danmark

Nikodan@nikodan.dk