Unique Solutions

UVC-Tunnel XP600

UVC-Tunnel XP600

This piece of special machinery will sterilize and disinfect the surfaces of all types of incoming products. We have standardized three different models of the UVC Tunnel: Waterfall, High Speed and Wire Mesh. More infomation on the specific models can be find further down this page.

The XP600 system can treat objects like:

Bags, boxes, cans, packages, consumer goods - along with the contents of these, keeping in mind that they fit on the conveyor belt.

The UVC light can reduce bacteria and virus on the surfaces with up to 99 % - depending on time and effect. As the light only reaches the surface of the items passing through the uv sterillzer conveyor, and there are no other types of physical contact, there's a low risk of changing the technical properties of the product. This also means that there is no quarantine time or secondary chemical issues. Another advantage with using UVC light treatment for disinfection and sterilizing, is that it is an instant technology. This means that the system is active when turned on and inactive when turned off. There is no cooldown or unnecessary energy waste to consider.

If you are looking for a high quality uvc tunnel conveyor, then this system includes a wire mesh made from stainless steel. Also, the uv sterilization provided by this machine is caused by uv lamp disinfection, which ensures destruction of bacteria. This occurs since ultraviolet light is a form of electromagnetic radiation. Also, UVC's effectiveness is directly related to intensity and exposure time. Our UVC tunnel ensures a high degree of sterilization with resulting destruction of microorganisms.

The Tunnel is constructed in cooperation with NATDIS, who are experts in all that is UVC lights. Read more about their expertise of natural desinfection on their website:

Advantages of UVC treatment:

Does your company need a UVC Tunnel XP600, or something like it? Write us a message or give us a call!

- Effective disinfection with no contact

- Continuous and uniform treatment without the use of chemicals - No waste

- 100% surface treatment with one time run through

- No known resistances with UVC treatments

- Can be fed automatically - for instance, by robot

- Low service demands - Change of lightbulbs every 8-10000 hours

- A cheap alternative to other methods of disinfection

- Does not expose the products to high temperatures or fluids

- Large capacity and flexible in regards to conveyor speed, dosage and placement

Product information:

Width: As required (+/- 50 mm)

Height: As required (+/- 50 mm)

Length: As required (+/- 50 mm)

Speed: Up to 1 m/s

Surface: Glassblown or grinded

Cleaning: Belt can be taken off for cleaning without tools.

Protection class: IP65.

Download the brochure

Our Models

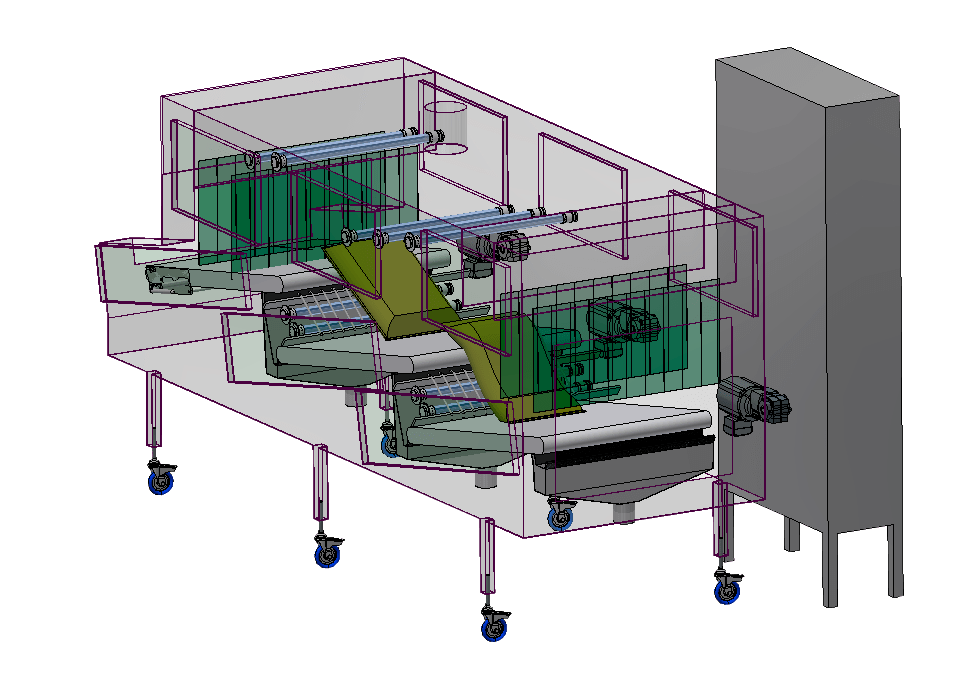

Waterfall Model

This unit is designed with three conveyors that will transport the item over two drops. Here the underside of the item will be treated with UVC, as it ‘drops’ down on the next conveyor, guided by a stainless steel mesh.

The Waterfall Model is useful for handling typical ‘soft’ items, like bags and packages. It can be used for material going in to a production area, handling items going into an automatic storage system or bags with, for instance, items from other countries, feed for farms or minerals.

It can handle items with a maximum of 35 kg and a minimum of 300 grams, with a maximum width of 800 mm and a minimum of 50 mm. The belt runs with a slow to moderate speed; up to 0.1 m/s.

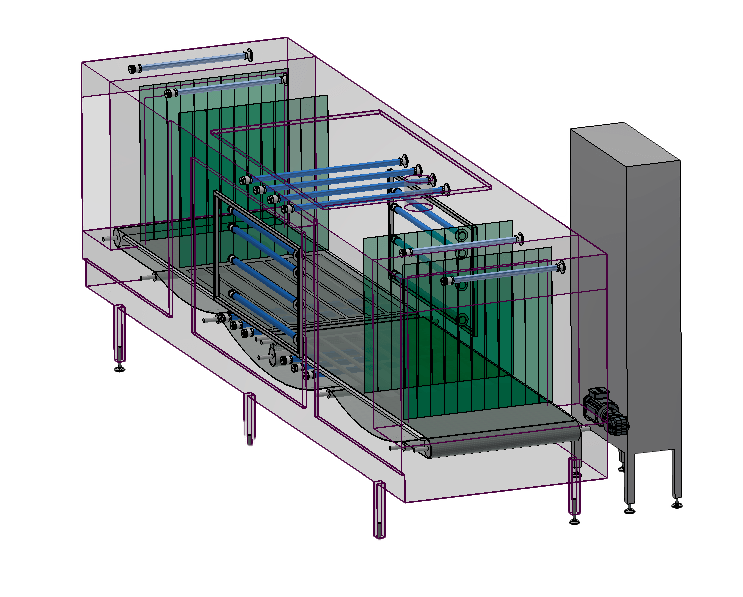

High Speed Unit

This unit is designed with a flat floor that transports the items through it by 100 mm conveyor belts. In the space between the conveyors there is quartz glass, which is where the item gets treated. The model has two sections to ensure full treatment.

The High Speed Unit is useful for the package industry, to disinfect items going in and out of warehouses, or as a part of a luggage handling system for hotels or airports, for customer security.

It can handle items with a maximum of 35 kg and a minimum of 1 kg, with a maximum width of 800 mm and a minimum of 200 mm. The belt runs with a fast speed; up to 1 m/s.

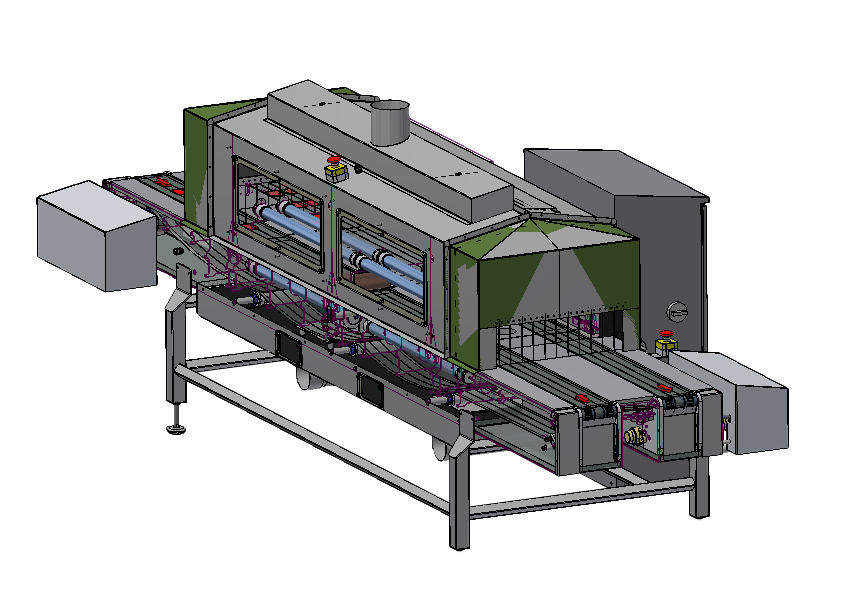

Wire Mesh Unit

This unit is designed with a mesh net that transports the items through it. With the help of a special loop, the items change position on the band during the passage, thereby enabling 360 degree treatment of the items. The model can be customized per the customers needs, for instance with 2 conveyors going opposite directions for an assembly line with robots.

The Wire Mesh Unit is a special design, that can be used for various different items and situations. It can, for instance, be used for disinfection of boxes going into clean zones, for parts of a production that need to be disinfected before package or assembly, or for disinfection of produce and consumer goods.

There is no immediate limits to the size and weight of the items going through this model of UVC tunnel. The belt(s) run with a slow to moderate speed; up to 0.1 m/s.

Lets stay in touch

Contact us

+45 39 30 43 16

Fællesvej 9, DK-8766 Nr. Snede, Danmark

Nikodan@nikodan.dk