Unique solutions

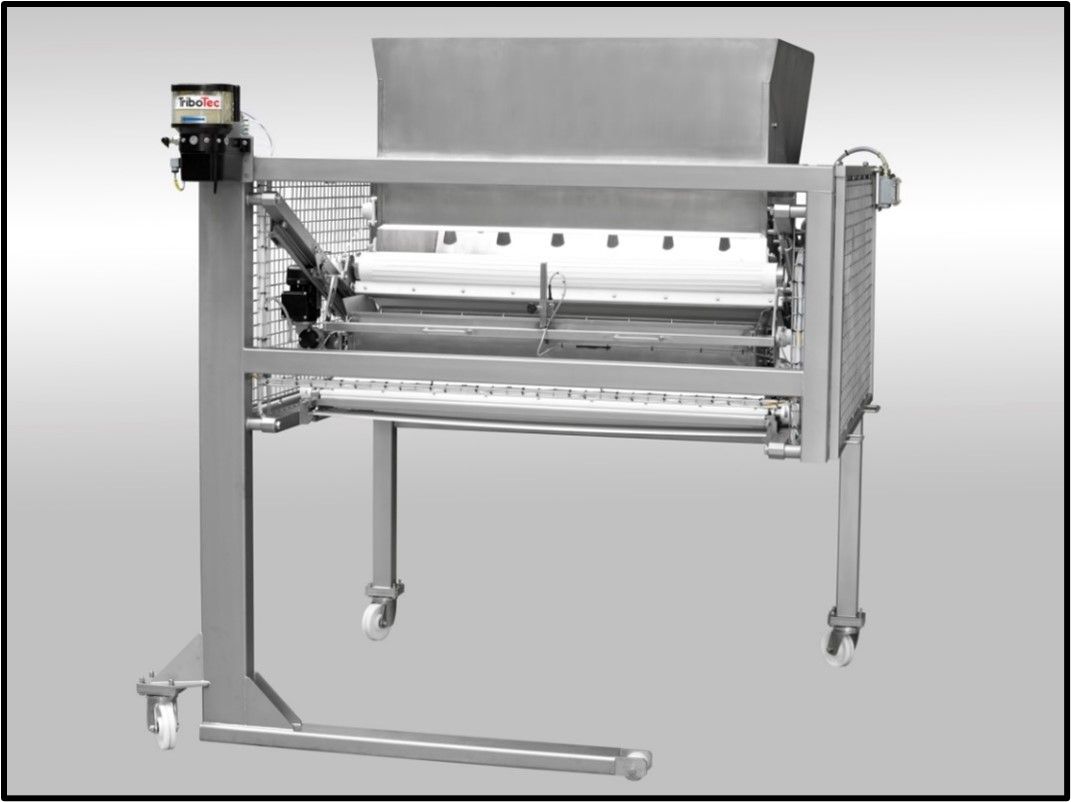

Muesli Sprinkler 1080

Muesli Sprinkler 1080

This unit helps distribute a continuous spread of muesli, or granola, and similar sticky products. After the product is fed to the unit, either manually or through a conveyor, the product is stirred and distributed in a thick and even layer to a conveyor belt. From here, the product is ready to be run through an oven system. Layer thickness and speed can be adjusted for production needs, to make sure the product can be transferred correctly to the oven conveyor belt.

The Muesli Sprinkler is easy to disassemble and easy clean, making sure it's not an issue to accommodate the strict hygiene requirements that exist in the food industry. The unit is furthermore built with a strong steel frame and lockable wheels. This way, it's easy to move the Sprinkler out of the way for cleaning, maintenance or in case of production remodeling.

Advantages of a Sprinkler

- Large capacity and flexibility in relation to conveyor speed, dosage and placement

- Even handling of sticky products

- Easy disassembly for cleaning and maintenance

- Made with wheels to enable transportation of unit, either for cleaning, maintenance or remodeling

- Potentiometers for regulation of the mixer and sprinkler belt

- Comes with a CE marking and full documentation

If you're interested in more information on this sprinkler unit or other NIKODAN solutions, then contact us by sending us a mail or giving us a call.

Product information:

Width: Standard 1991 mm or as required

Height: Standard 2374 mm or as required

Length: Standard or as required

Speed: Up to xx product pr. Minute ( Servo)

Surface: Glaspeened, grinded as option.

Cleaning: Belt to be taken off for cleaning without the need of tools.

Protection class: IP65.

Download the brochure

Lets stay in touch

Contact us

+45 39 30 43 16

Fællesvej 9, DK-8766 Nr. Snede, Danmark

Nikodan@nikodan.dk