The product is then transported to, for example, an oven or an air dryer.

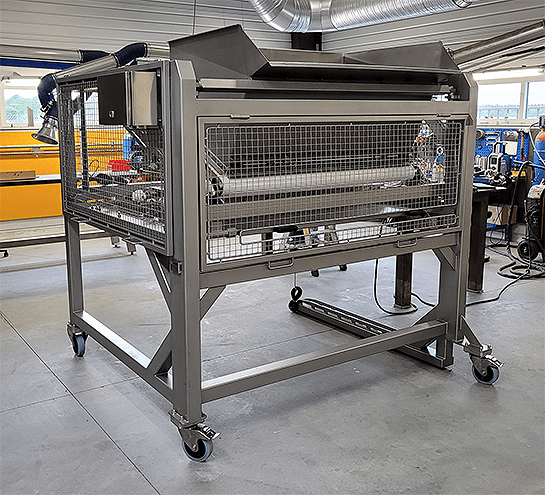

The unit is easy to disassemble and clean, which ensures that it will not be a problem to meet the strict hygiene requirements in the food industry. The sprinkler is also built with a strong steel frame and lockable wheels. It is therefore easy to disconnect and move the unit in connection with cleaning and maintenance, or in the event of a rearrangement of the production structure.

Advantages of a muesli sprinkler:

– Large capacity and flexible in relation to belt speed, dose and location.

– Smooth handling of sticky products

– Easy to disassemble for cleaning and maintenance

– Manufactured with lockable wheels to enable easy transport of the unit, either for cleaning, maintenance or replacement

– Potentiometers for regulating the mixer and sprinkler belt

Comes with CE marking and full documentation

– We are of course available if you want more information about the product.

Examples of other products and solutions we offer:

– depalletizing equipment

– shuttle conveyor

– infeed

– process equipment

– shuttle conveyor system

– depalletising of frozen blocks

– depalletizing machine

– conveyor systems

– reject conveyor

– infeed conveyor

You can read more our products and solutions here:

https://nikodan.eu/solutions/