New smart cutting machine for modern bread production.

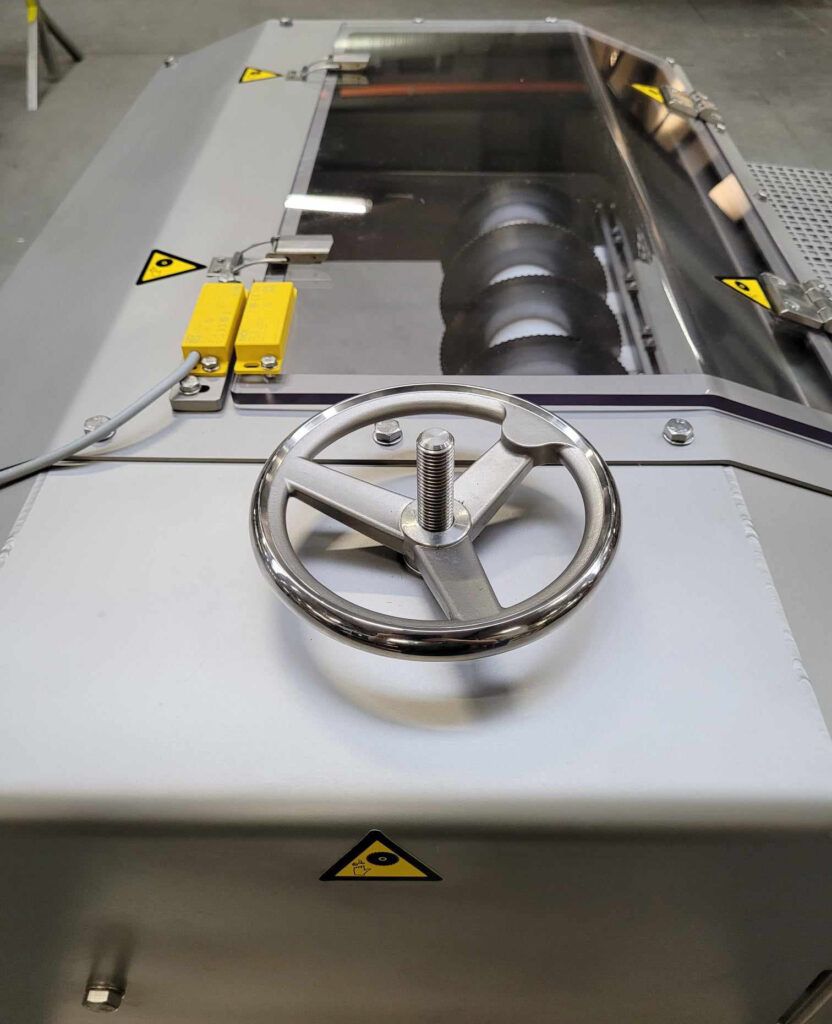

We recently produced the machine below for a customer who produces bread. The machine has a series of rotating cutting knives that are made to cut raw dough. Typically, the machine will be placed over a conveyor system where raw dough passes by on a belt. The machine is built in stainless steel and complies with the various hygiene requirements found in industrial bakeries.

To make the work safe for the employee who operates the machine, the machine is equipped with guards over the knives and warning labels that warn of rotating knives in the machine. The machine also has a control panel where, among other things, you can regulate the speed, start and stop.

A handwheel on top of the machine also makes it possible to move the knives up and down such that they have the correct position for the dough to be cut. If you would like a further chat about this machine or our other products, please contact us by phone: +45 39 30 43 16 or e-mail: salg@nikodan.dk.

This dough cutting machine has several significant advantages for factories that produce bread and are considering investing in this advanced machine:

Increased productivity:

As mentioned, the machine is equipped with rotating cutting knives that are tailored to cut raw dough. This significantly automates and accelerates the cutting process, leading to a significant increase in productivity. The factories that use the machine can thus produce more bread in a shorter time.

Consistent quality:

The exact and precise cutting offered by the machine ensures a uniform quality in the sliced bread or raw dough. This is essential to meet customer expectations and maintain product quality.

Hygiene and food safety:

The machine is constructed of stainless steel and meets the hygiene requirements for industrial bakeries. This helps to ensure food safety and compliance with industry standards.

Security:

With shielding over the cutting knives and warning labels, the safety of the employees is a high priority. This reduces the risk of occupational accidents and creates a safer working environment.

Flexibility and ease of use:

The control panel allows users to adjust speed, start and stop, making it easy to adapt the machine’s operation to specific production needs. The handwheel on the top makes it possible to fine-tune the position of the knives for optimal cutting.

Effective resource utilization:

The automated cutting reduces waste and minimizes the need for manual labor, making the production process more efficient and cost-effective.

Scalability:

The machine can be easily integrated into existing production lines and conveyor systems, making it ideal for both small and large industrial bakeries that want to increase their capacity.

As a manufacturer of industrial dough cutting machines, we also have several other machines that are used in connection with the production of bread and confectionery. You can read about these machines here: